A Unit Of Dencil Group Of Companies

Since 1992, Dencil PUMPS & SYSTEMS PVT LTD has been at the forefront in developing innovative designs in the manufacturing of high quality Dosing Metering Pumps, Dosing Systems, High Pressure Triplex Pumps, Centrifugal Pumps and various other pumps and Agitators for industrial as well as non-industrial applications since the begining of its activity.

Pre Sales Services:

- One Stop Solution

- Product Support

- Genuine Spares

- Training

- Maintenance Contracts

Our Solutions

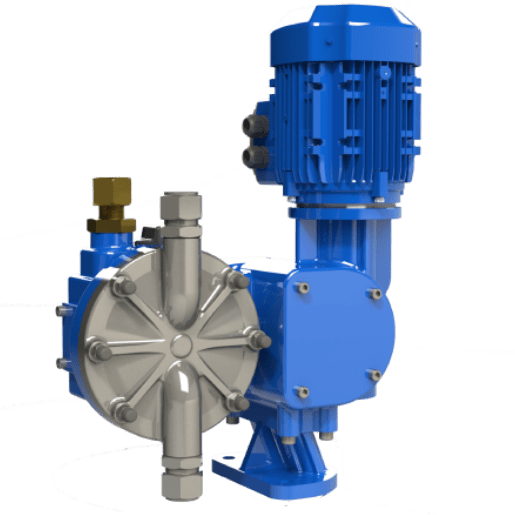

DIAPHRAGM PUMPS are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

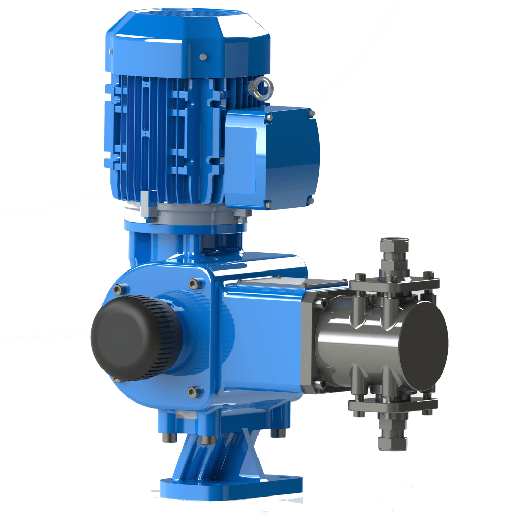

A Simplex Pump is a reciprocating pump. This pump has a single liquid cylinder which forces liquid out through the top outlet on both the in and the out stroke.The Simplex Reciprocating Plunger Pumps is a packed plunger pump designed for heavy duty , continuous, accurate metering at higher flow rates and/or pressures. The positive displacement supplies a simple and virtually maintenance-free approach to accurate feed.It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger. We can vary the capacity from zero to maximum by stroke length adjustment mechanism. The reciprocating motion of a plunger with ball check valves on each side of the pump body creates the pumping action.

It is used for highly corrosive chemicals in process industries replaci ng highly expensive materials like Hastelloy, Alloy – 20, SS 316, Monel etc. Liquid contact parts are made of moulded polypropylene. Standard dimension pumps are provided with Blue Asbestos Gland Packing or Internal or External Mechanical Seal. Impeller is moulded with Hastelloy, Alloy – 20, SS 316 inserts. One piece sturdy solid moulded volute casing is designed to avoid breakage of polypropylene flanges at suction and discharge ends. Semi open impeller with metallic insert ensures smooth running. Loosening of impeller is prevented by dome lock nut made of Hastelloy, Alloy – 20, SS 316 according to liquid to be handled. Shaft is made of SS 316 and sleeves are made of Hastelloy B or C, ceramic Alloy – 20, Monel etc. according to liquid to be handled. Wide ranges of models are available to cope up any requirement of head and capacity from heavy duty couple pump to small, monoblock laboratory pumps.

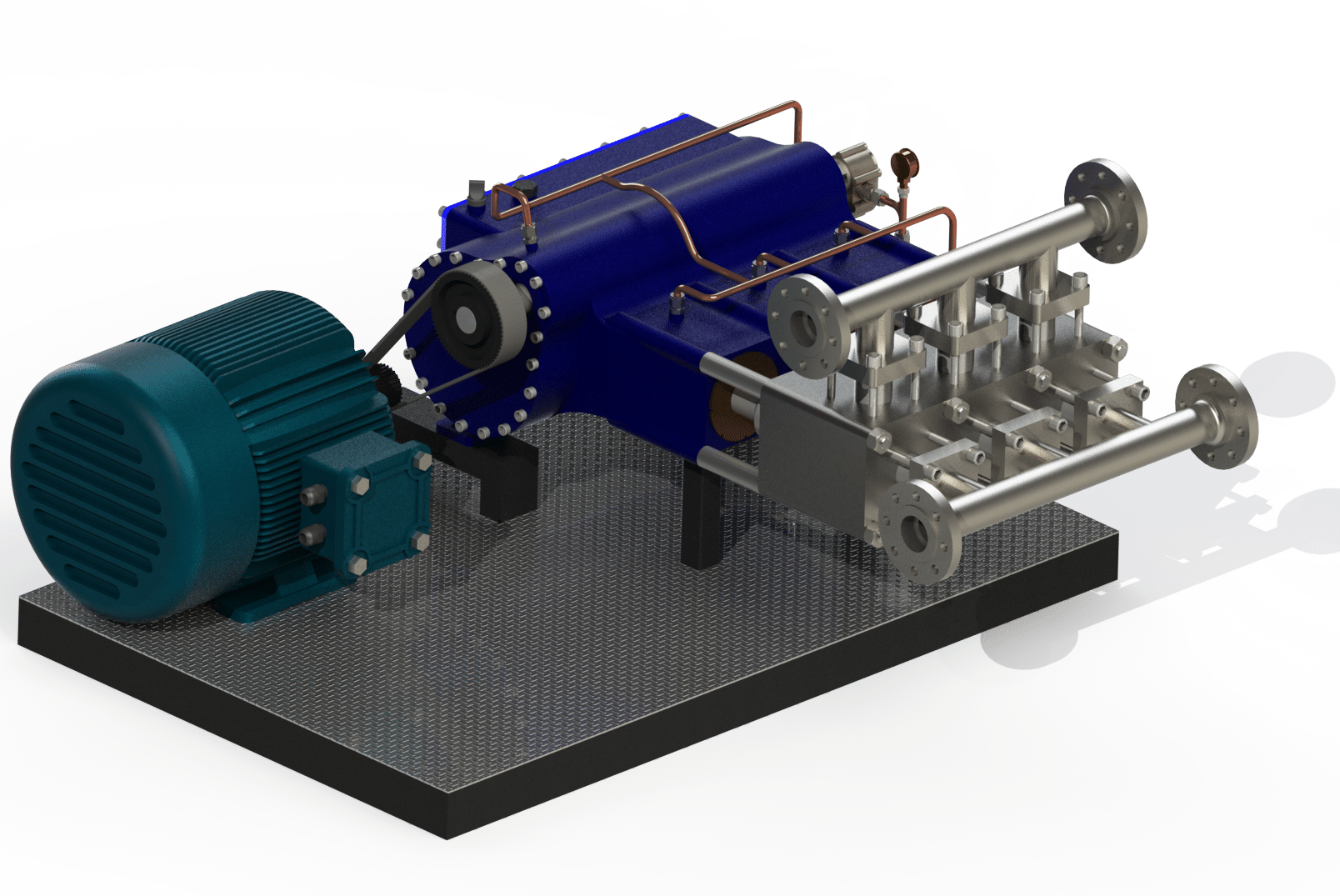

Dencil Pumps is one of the best and a leading Triplex Pumps Manufacturers in India. Our Triplex pumps are essentially plunger pump with 3 cylinder and 3 heads. They are essentially used for pumping high quantity / low quantity fluid at high pressures. Flow of liquid will be continuous due to the operation of 3 plunger in a cyclical manner. The dry section are made with specifically chosen material and manufacture to give the best performance for a long period of time. Similarly the fluid end operates are chosen as per the customer’s requirements or demand of the fluid. The Triplex Pumps manufactured by us are produced with high quality Raw Materials. This ensure a long and reliable life of Triplex Pumps manufactured. The offered Triplex Pumps are manufactured as per set industry standards to satisfy the Governing Norms. We also provide Customized Triplex Pumps as per Client specifications and demands to ensure customer service and satisfaction at its best.

Dencil Pumps is one of the most renowned High pressure Pumps Manufacturers in India. High pressure pumps and frameworks fabricated by Dencil Pumps are ideal for client needs. Our high pressure pumps run from power appraisals up to 1000HP, release up to 2500 LPM (150 M3/Hr) and working pressures up to 20,000 PSI (1400 Kg/Cm2). The pumps are accessible in electric and also motor driven engine with different choices of coupling and mounting according to the client’s application requirements. Apart form that, these High pressure pumps are strong and formulated for both discontinuous and persistent obligation cycles. Dencil Pumps, likewise makes accessible extras required for the High pressure pumps according to particular utilization like cleaning / flying connections.Our high pressure pumps are the most creative and are highly productive for different applications like testing, showering, cutting, cleaning, descaling, exchanging of liquids, pressure infusion and so on. Thats why, we are known to be the best High pressure pumps Manufacturers in India and Abroad.

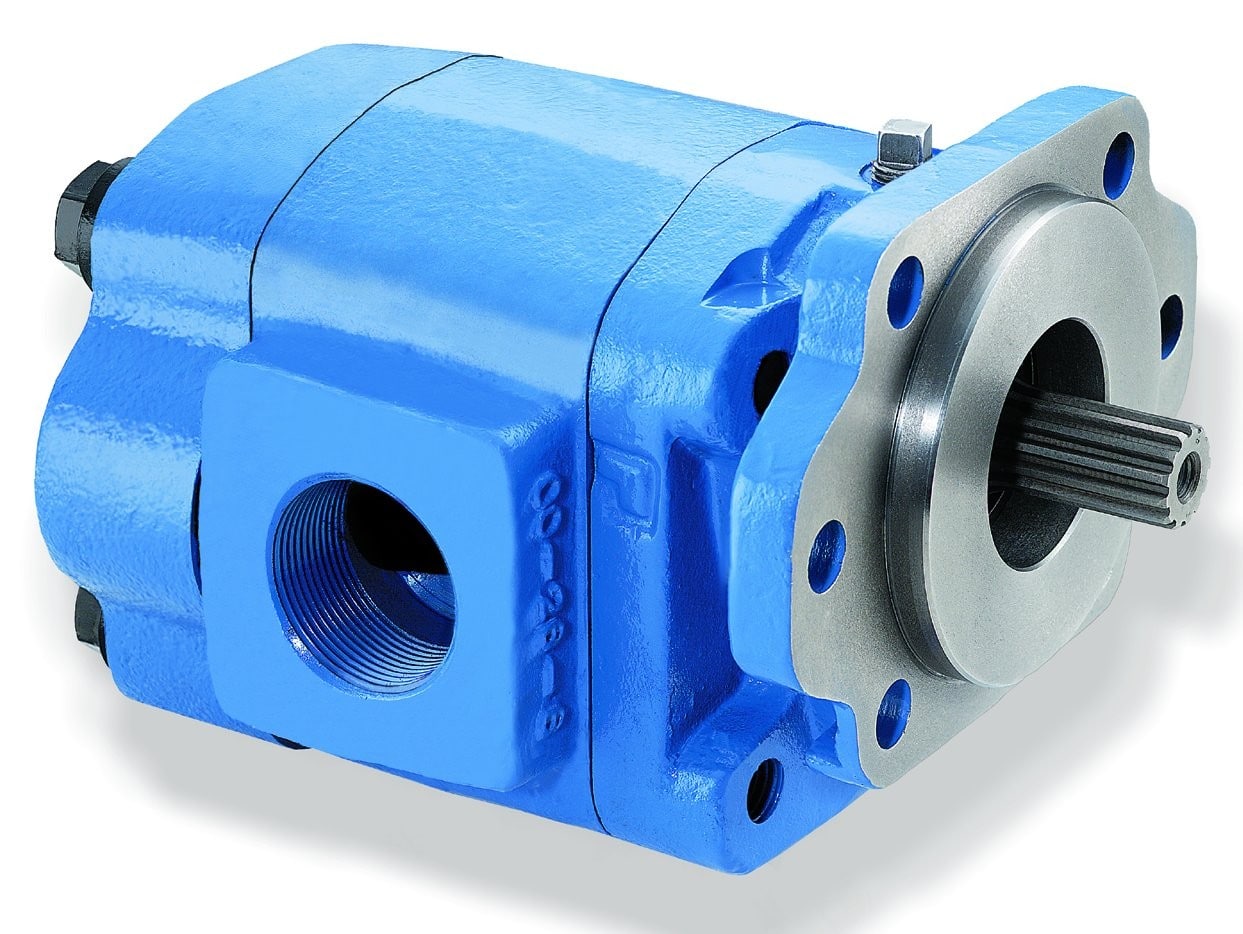

Dencil pumps offers heavy-duty gear pumps , which is useful for pumping and transferring of heavy fuel oils, like LDO, FO, LSHS, HSD, crude petroleum, wax slurries, starch solutions, glue, etc. Generally made of iron Alfa pumps are also available in cast steel, stainless steel. Dencil Pumps is one of the finest and the most promising Gear Pumps Manufacturers in India. Being the most advanceed and renowned Gear Pumps Manufacturers, the offered Gear Pumps are of high quality and manufactured as per client’s reuqirements to ensure maximum client retention and satisfaction at the customer’s end. We perform various types of quality checks periodically to see to it that the quality of the Gear Pumps is maintained. This in turn, results in long product life and less maintenance costs. Also, the quality control tests are performed by industry experts to confirm error-free experience for the user.

Dencil Pumps & Systems Pvt. Ltd are specialists in manufacturing Agitators and Industrial Mixers. We are a prominent Agitator Manufacturers in the country. The offered Agitator is manufactured out of various grades of steel such as Carbon Steel, Stainless Steel and also Special Grades of Steel and Alloys such as 904L, Titanium, Hast alloy and Duplex Steel.

Agitators are also given specialized coatings and lining consisting of Rubber Lining, Teflon Lining, PP Lining and FRP Lining. Depending upon on the processing conditions, various sealing arrangements such as Single Mechanical Seal, Double Mechanical Seal, Stuffing Box and Lip Seal can be provided to suit the requirements.We ensure that we, at Dencil Pumps, being a leading Agitator Manufacturers provide supreme quality of Agitators to our clients. They are manufactured from raw materials that are advanced and maintained in a good working condition. We also perform various quality checks and tests to assure the working stability and reliability of the Agitator manufactured by us. We believe in complete optimization of resources and quality assurance and thus never compromise with the product quality and the quantity offered.

- Dosing System(Skid Mounted)

- Injection Skid Packages

- DRA Skid

- Pump Skid Unit

- Blending Skid

- Gas Metering Skid

- Pressure Vessel & Storage Tanks

- Offshore Tanks

- ISO Tank Container